The complexities of onsite network modernization

Integrating and installing networking components and systems for U.S. military and government organizations traditionally has been expensive and time-consuming. With globally diverse locations and technically complex secure government networks and advanced technology, skilled staff would often spend weeks, or even months, onsite to ensure everything worked properly. The unknowns of each site also increased the risks of errors and other issues requiring sourcing of additional skilled workers or parts. This, in turn, impacted budgets and ultimately delayed the delivery of needed capabilities to the armed services and other government organizations.

CACI helps government customers avoid these complications and complete their network modernization upgrades in a more timely and cost-efficient manner through its high-tech, multi-lab environment in High Point, North Carolina. For more than 30 years, our NetMod Labs has served as an in-house network demonstration and prototyping facility. The multi-lab facility allows engineers to test and stage both unclassified and classified networks before deployment to streamline onsite installation.

200+

Projects and sites supported

6

Simultaneous projects supported

in the main staging facility

2 to 12

Weeks of onsite work saved

per project due to testing

Designing a high-tech lab to modernize the test and install process

Government-owned networks, particularly those related to defense, come with a long list of security and capability requirements, classification levels, and other complications. For a laboratory environment to fully support the unclassified and classified network needs of a government customer, CACI had to ensure the necessary lab infrastructure resulted in a flexible, multipurpose facility. For example, labs would be needed for prototyping new solutions, wireless experimentation and integration, cybersecurity management, network integration and testing, training, staging and client demos, and more.

The lab would also need to provide the necessary, and often demanding, power and cooling needs associated with server-based and other electronic equipment, and be capable of testing and integrating Commercial Solutions for Classified (CSfC) networks. Because CSfC also requires a lengthy cyber accreditation process, the appropriate cyber resources would need to be in place so cyber accreditation packages could be submitted to the NSA and internal accreditation authorities. The lab, which had to be stateside to meet security and operational supply chain needs, also required designs that support in-person and virtual collaboration.

Delivering network support for more than 200 projects and counting

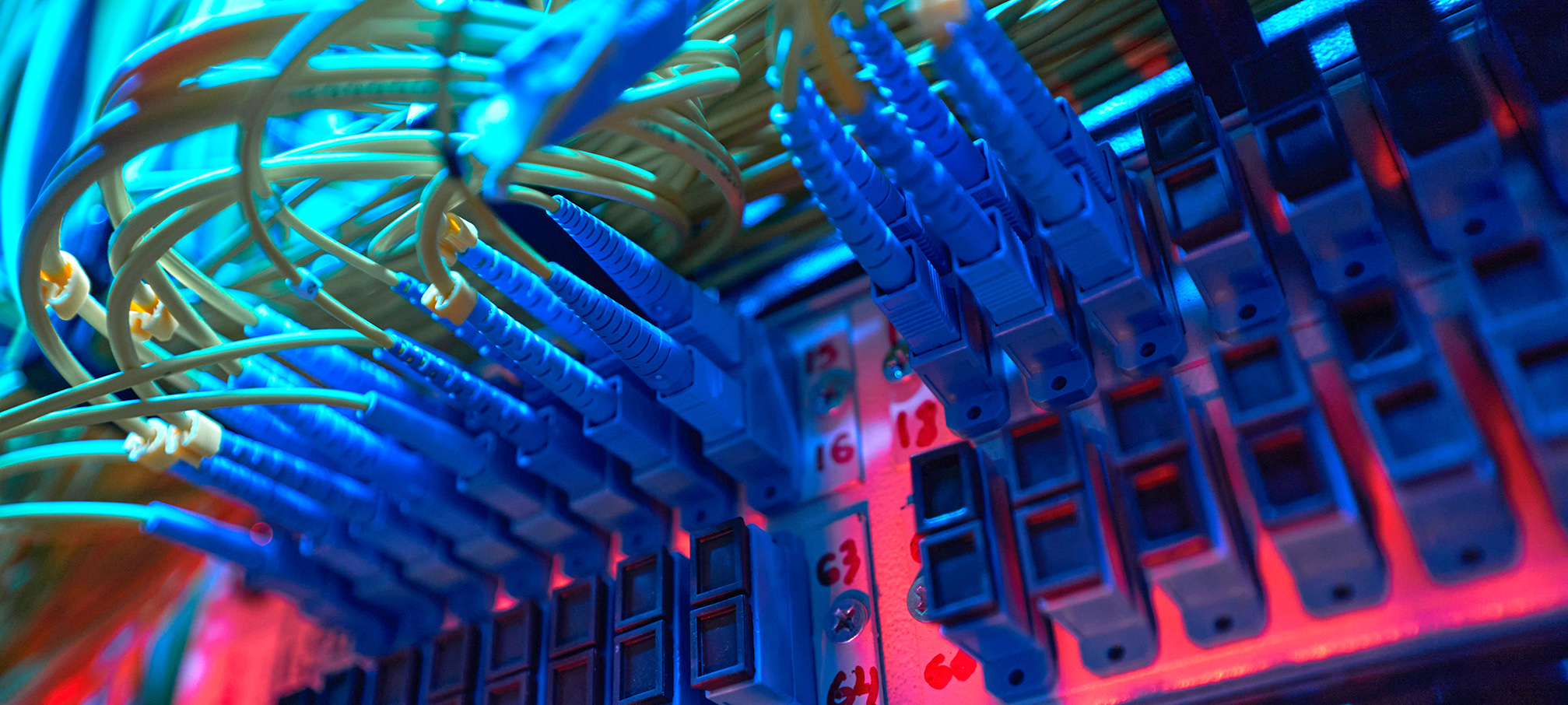

CACI’s NetMod Labs includes both an office wing and a lab wing, and the center point of the lab is the staging facility. The lab wing is interconnected, allowing for flexibility of use as required by the projects in progress. It includes a network operations center that serves as the main control of customer networks, a wireless lab that facilitates testing cellular and radio wireless solutions, and a prototyping network lab that enables developing custom solutions or projects in progress, such as software-defined networking.

The staging facility is used for testing, integration, staging, and demos. It includes a series of racks that can be used for one to six projects simultaneously. With the appropriate power, HVAC, communication, and cabling already installed, CACI engineers can take raw customer products into the room and assemble, inventory, label, integrate, test, and prepare them for deployment. This has resulted in extremely streamlined onsite experiences as compared to the traditional approach, with installation and integration completed sometimes in days rather than weeks or months.

The facility provides CACI engineers with a place to train on the new equipment themselves, so they become familiar with the new technology before work begins. It also offers a place for vendor engineers to train, including a classified space for learning about the complexity and requirements of the CSfC efforts. Each lab at High Point contains ample power, and each unclassified room is connected to allow for overflow and collaboration between rooms and global locations as required.

The modern iteration of the lab has successfully integrated, tested, and supported more than 200 programs for customers such as the Army, Air Force, and other DoD organizations across Europe, Asia, Hawaii, and the continental U.S. The lab has also supported critical non-defense networks, such as a U.S. Department of Agriculture network for forestry services and firefighters out in the field.

Benefits of a network testing center

- Reduces travel, risk, time, and expense.

- Removes initial limitations on power and access by co-locating equipment in one environment vs. multiple onsite buildings.

- Enables engineers to more efficiently build out infrastructure logistics.

- Equipment is fully prepared, inventoried, labeled, assembled, and tested before it is deployed to ensure streamlined onsite installation.

“It streamlines onsite activity. We've worked through all the hurdles. We've done the integration troubleshooting that often occurs — we've already tackled all of that. Now, it's plugging up known entities and when you get to the site, we're just establishing connectivity between their buildings and we know the solution works.” said Mitchell Poole, engineering lead for CACI's Network Integration Solutions.

Modernizing for the future of testing

NetMod Labs is undergoing its own modernization to add more robust power to enhance rack positions and ensure future infrastructure capabilities. This includes increasing the HVAC capacity by fourfold to ensure proper cooling for larger solutions. With these upgrades, the lab will be able to expand its network operations center as part of a larger-scale pursuit involving the management of military base networks and the use of customer equipment to stage a production network for testing and interconnecting global nodes for a global army.

The lab will also be maintaining lab solutions and test environments that are a replica model of the real solution for its customers. Within these environments, both CACI and customer experts can test, troubleshoot, and integrate patches and updates as they occur in a controlled environment, which minimizes risk when solutions are deployed onsite into production systems.

“These lab enhancements make the sky the limit. We can spread out if we need more room, we have flexible lab storage spaces, and we have the ability to work on almost anything that be done within an unclassified environment and in some classified spaces.” said Chris Ottinger, CACI systems engineer.